The process is based on conveying the strip through hydrochloric acid baths to dissolve the surface oxides. The pickling process largely depends on the chemical composition of the material, the temperature of the baths, bath agitation, acid concentration and the length of the tanks.

After the scales are removed, the strip is properly rinsed and an oil film is applied to guard against rust.

Pickling and Oiling process enhances the surface finish and improves the shelf life of steel.

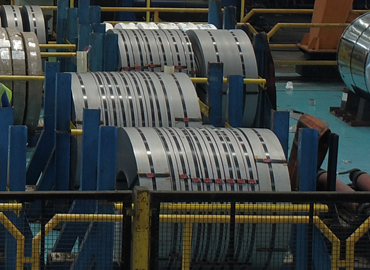

Our Pickling & Oiling facility at Ranjangaon, Pune is capable of producing Hot Rolled Pickled and Oiled coils which are used for a wide range of applications including Automotive, Strapping, Tubing, Rack Systems and various Stampings.