Catering primarily to the Automotive Segment Customers, Tube making and Construction Segment customers, these plants offer High End processing as per the stringent requirements of these sectors.

The Hot Rolled processing facility is located at Bara and is capable to process steel coils up to 12 mm thickness. The major USP of the plant is that it can process coils of UTS up to 800 Mpa.

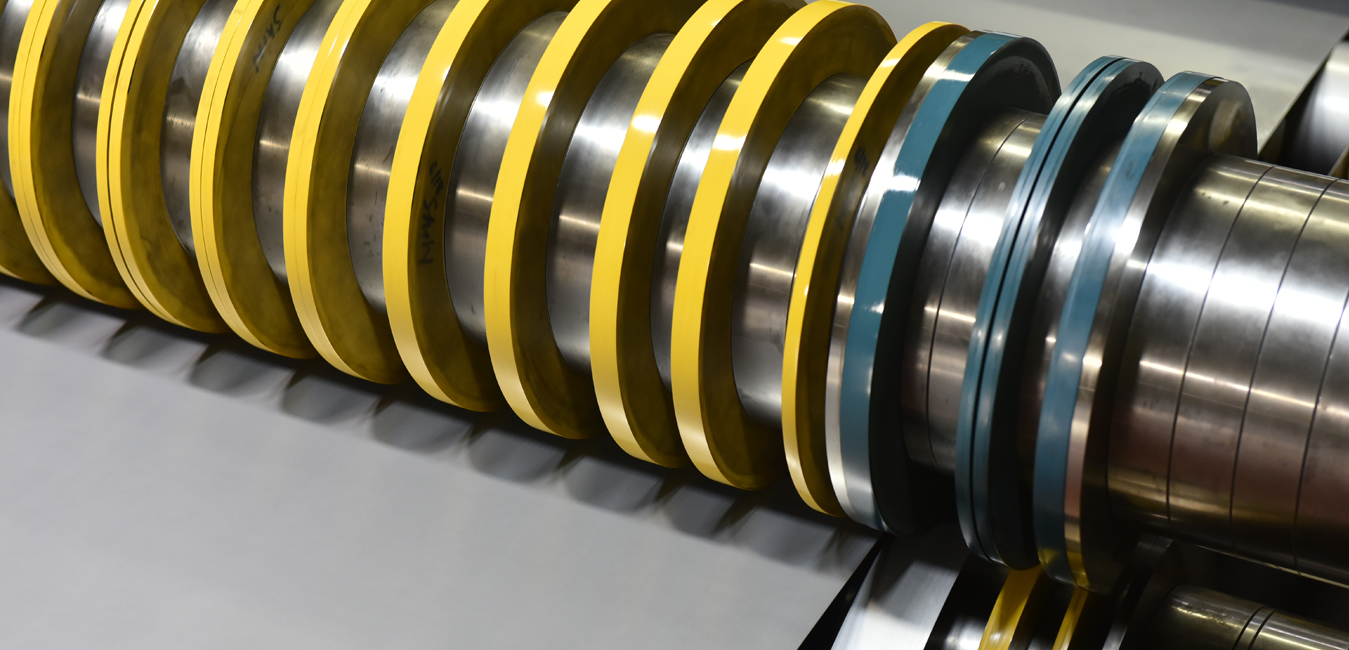

The Cold Rolled processing facility is located inside the Tata Steel Works and is capable of processing coils up to 3.2 mm thickness. The lines are capable of processing High Tensile material of UTS up to 700 Mpa.

The plant is also equipped with Roll Forming lines and Barrel Corrugators, which are used for corrugation of roofing sheets used in the construction industry. The USP of this plant is its Skin panel processing capacity, which serves major automotive customers.

The third plant is located within the Tata Steel Tube Division and mainly caters to the requirements of the Tube making industry. It can slit coils up to 9.5 mm thickness and 1700 mm width.

The Hot Rolled and Cold Rolled facilities serve some of the leading OEMs in the Automobile space such as Tata Motors Limited, Toyota Motor Corporation, TVS Motor Company, Hero Motor Corp, Honda Motor Cycles and Scooters India among many others.

Apart from the above mentioned customers, these plants also fulfil the requirements of Indian Railways, Packaging Segment customers such as E Con Packaging (P) Ltd. and Balmer Lawrie and serve the requirements of Tata Steel Tubes Division and Tinplate Company of India Limited.